Proactive risk assessment tool to identify and prevent potential product or process failures.

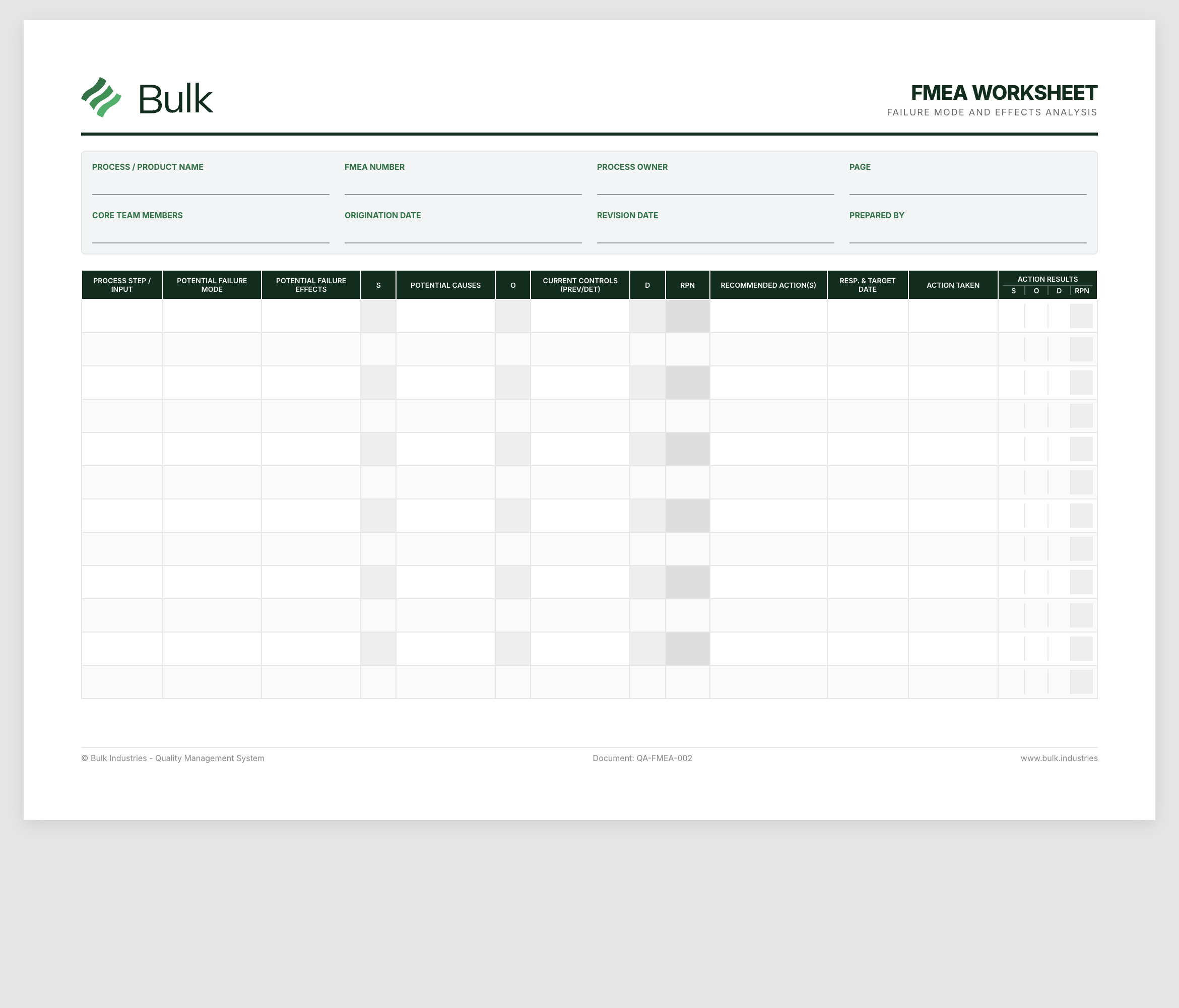

The FMEA (Failure Mode and Effects Analysis) Template is a systematic, proactive method for evaluating processes or products to identify where and how they might fail. By analyzing potential failure modes, their causes, and effects, teams can prioritize risks and implement preventive controls before problems occur. FMEA is required by IATF 16949 in automotive manufacturing and is a best practice across industries for advanced quality planning. This template uses the industry-standard Risk Priority Number (RPN) calculation combining Severity, Occurrence, and Detection ratings to focus improvement efforts on the highest risks.

Structured A3 format for systematic problem-solving using lean principles and PDCA methodology.

Systematic approach to identifying, investigating, and resolving quality issues with preventive measures.

Systematic inspection checklist to verify products meet all quality specifications and requirements.

Join manufacturing leaders who are turning operational noise into predictable production rhythm.