Verify incoming materials and parts meet specifications before they enter production.

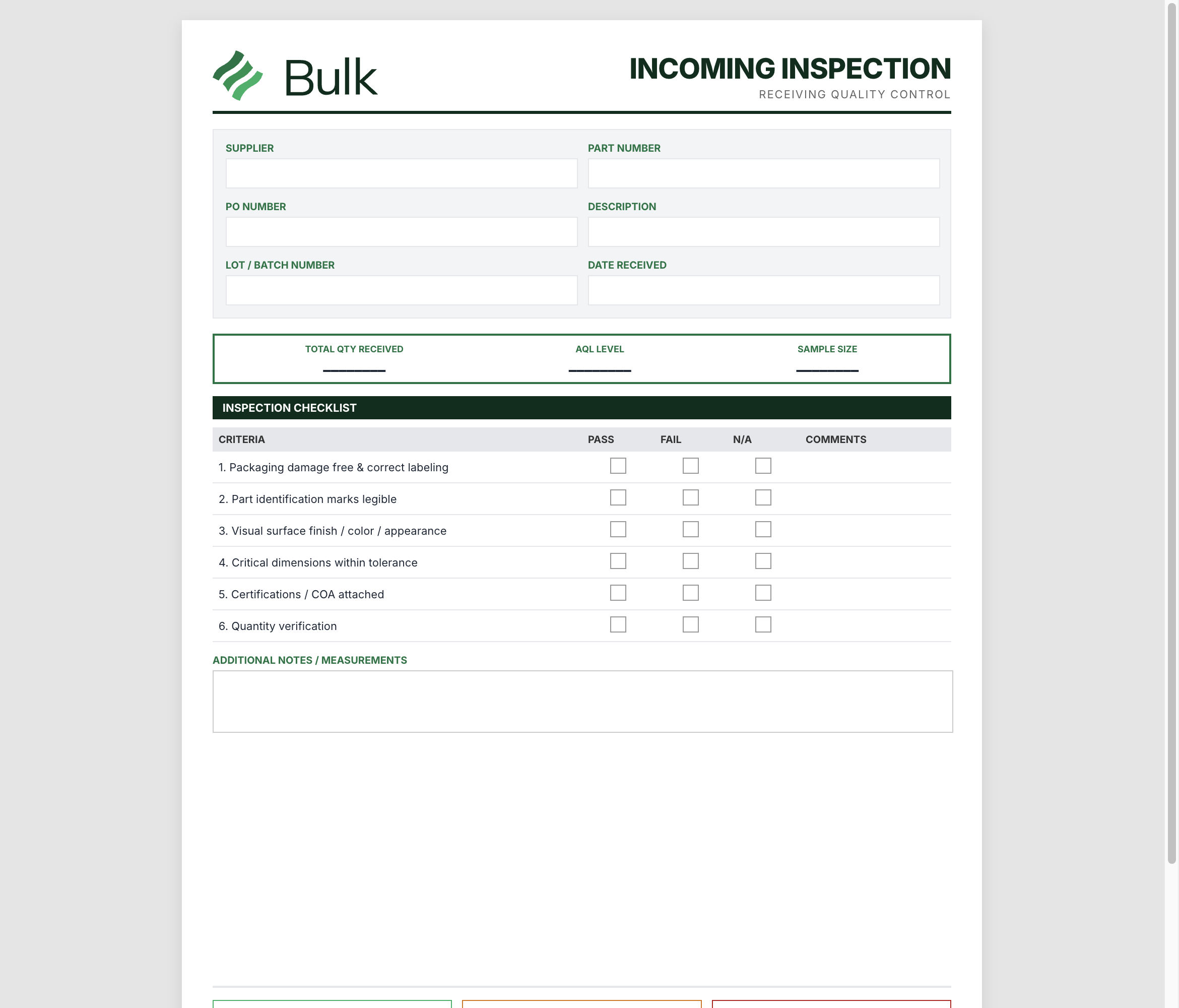

The Incoming Quality Inspection Form is the first line of defense against supplier quality issues entering your facility. This template provides a structured approach to receiving inspection, verifying that purchased materials, components, and assemblies meet specifications before being released to production or inventory. By catching supplier defects at receiving, organizations prevent costly production disruptions, scrap, and quality escapes to customers. The form documents visual inspection, dimensional verification, quantity accuracy, and material certification review, with clear accept/reject criteria and nonconformance escalation procedures.

Comprehensive verification that new or modified parts meet all design specifications and requirements.

Document and manage quality defects, deviations, and non-conforming products or processes.

Systematic inspection checklist to verify products meet all quality specifications and requirements.

Join manufacturing leaders who are turning operational noise into predictable production rhythm.