Plan and execute focused rapid improvement events targeting specific process problems.

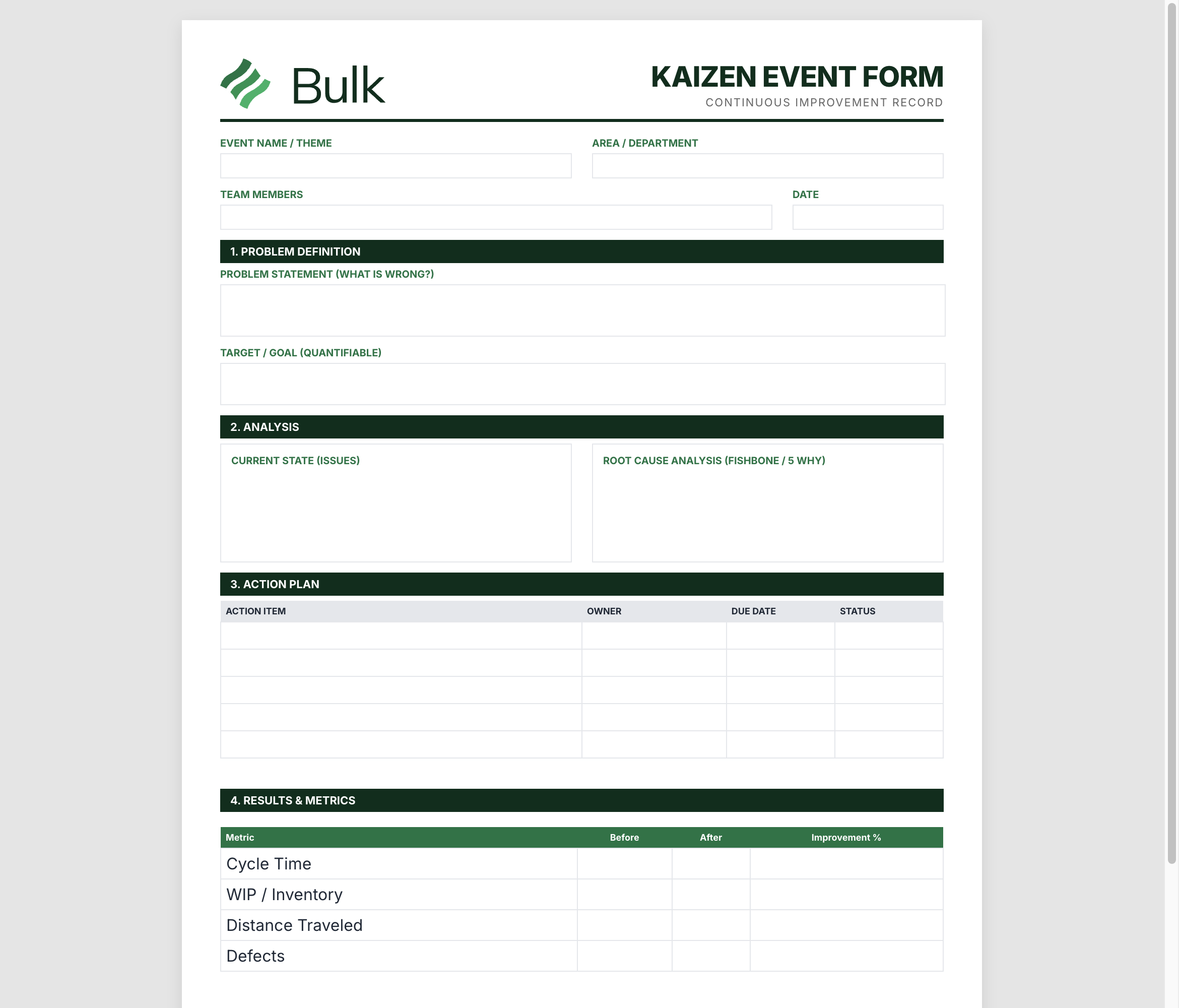

The Kaizen Event Planning Form structures focused, time-boxed improvement workshops that deliver rapid results. Kaizen events, typically lasting 3-5 days, bring together cross-functional teams to analyze a specific problem area, develop solutions, and implement improvements immediately. This template guides teams through event planning, goal setting, baseline measurement, solution implementation, and results verification. By concentrating resources and decision-making authority, kaizen events achieve in days what might otherwise take months, while building organizational problem-solving capability and continuous improvement culture.

Structured A3 format for systematic problem-solving using lean principles and PDCA methodology.

Track and optimize equipment setup times for faster changeovers and increased production capacity.

Visual tool for mapping material and information flow to identify waste and improvement opportunities.

Join manufacturing leaders who are turning operational noise into predictable production rhythm.