Document and manage quality defects, deviations, and non-conforming products or processes.

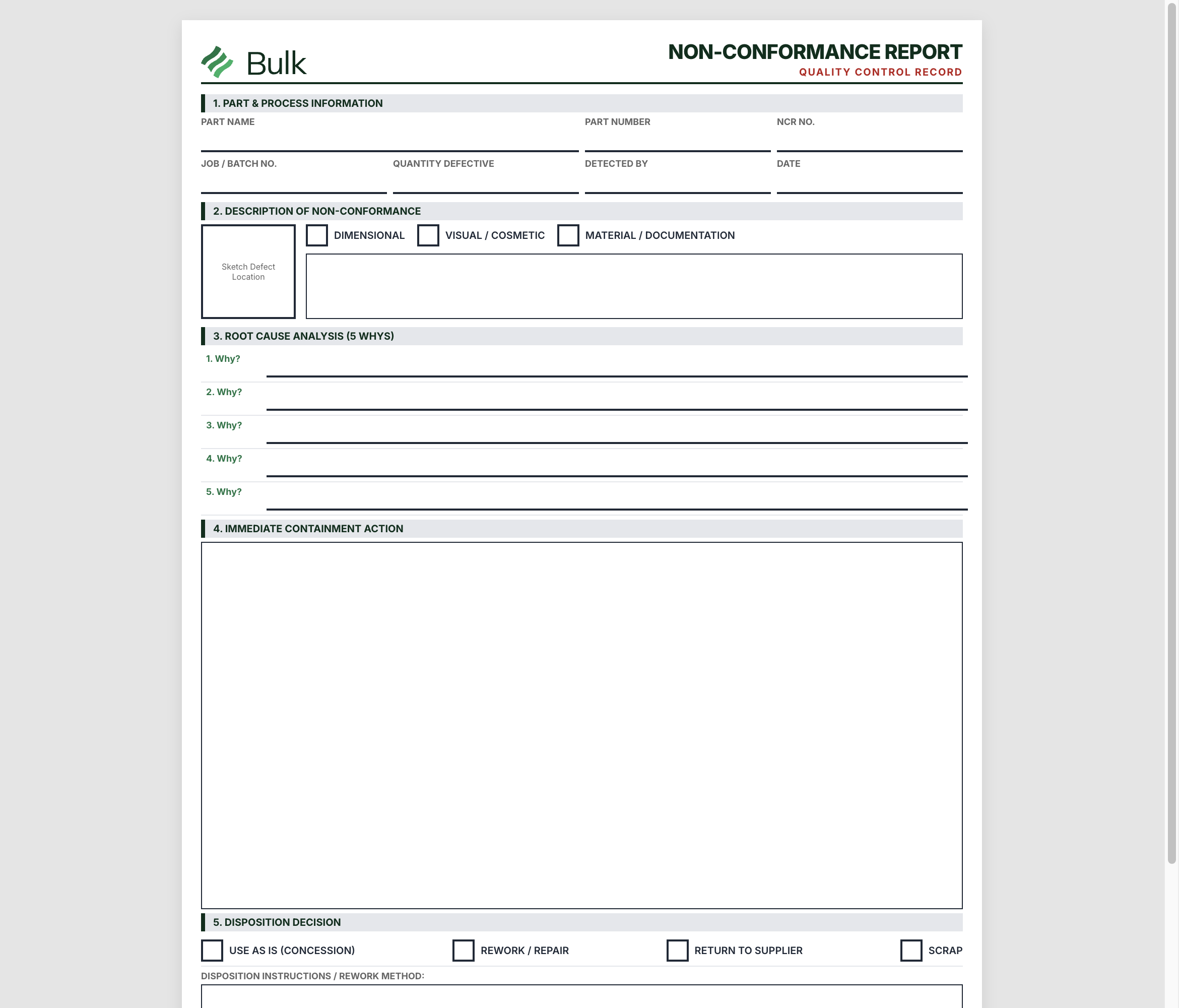

The Non-Conformance Report (NCR) is a fundamental quality control tool for identifying, documenting, and dispositioning products or processes that don't meet specifications. This template captures detailed information about the defect, affected quantity, root cause, and disposition decision (use-as-is, rework, scrap, return to supplier). NCRs provide traceability for quality issues, support containment actions to prevent shipment of defective products, and trigger corrective actions to prevent recurrence. The report also documents costs associated with non-conformances, helping quantify the cost of poor quality and justify improvement investments.

Systematic approach to identifying, investigating, and resolving quality issues with preventive measures.

Verify incoming materials and parts meet specifications before they enter production.

Systematic inspection checklist to verify products meet all quality specifications and requirements.

Join manufacturing leaders who are turning operational noise into predictable production rhythm.