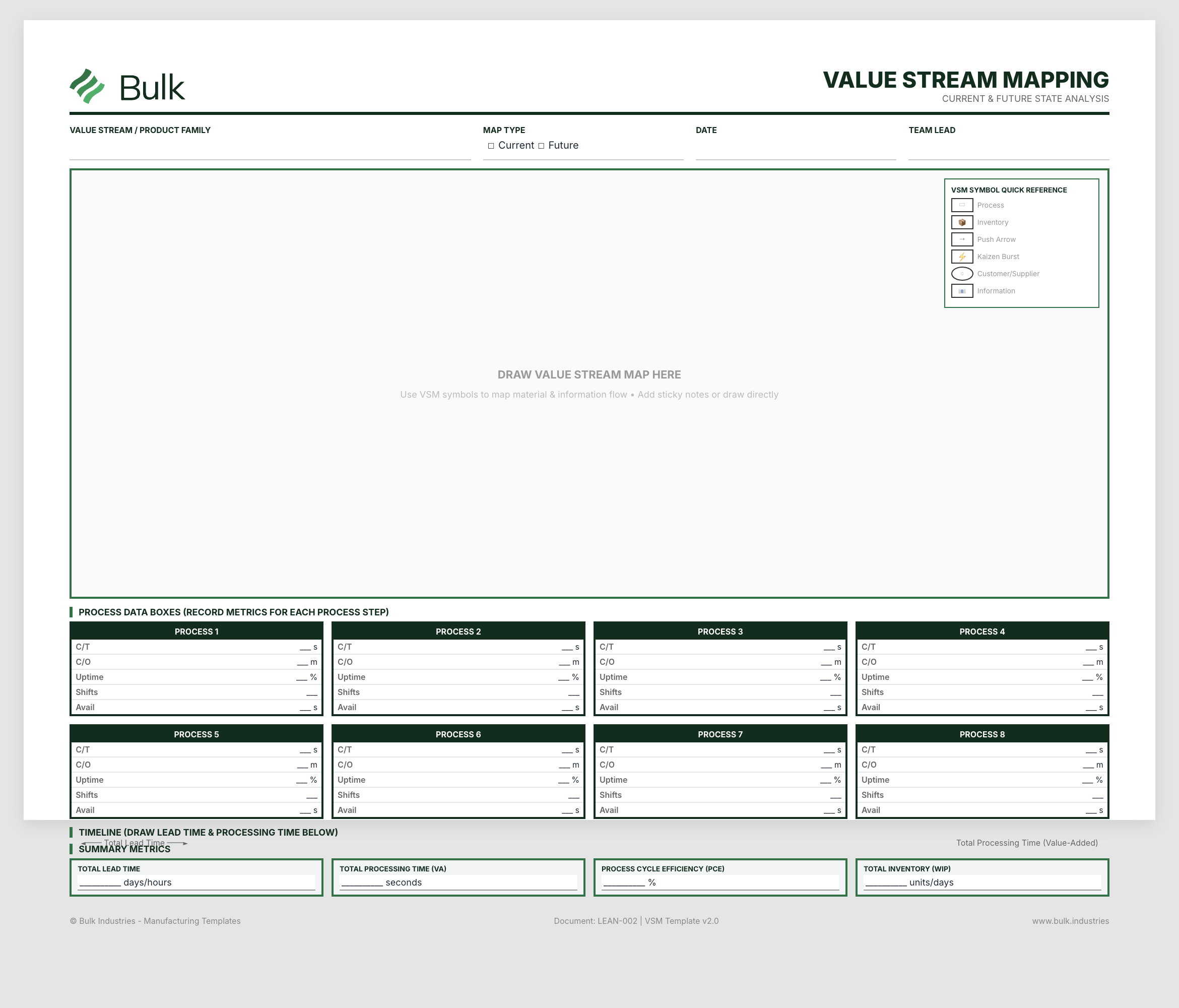

Visual tool for mapping material and information flow to identify waste and improvement opportunities.

The Value Stream Map (VSM) Template is a powerful lean tool for visualizing the current state of material and information flow from raw material to customer delivery. Value stream mapping reveals waste hidden in the overall process - excess inventory, waiting time, unnecessary transportation, overprocessing - that individual process observations miss. This template uses standard VSM iconography to document process steps, cycle times, changeover times, inventory levels, and information flow. By calculating value-added vs. non-value-added time, teams identify dramatic improvement opportunities. The template supports both current state documentation and future state visioning, providing a roadmap for lean transformation.

Structured A3 format for systematic problem-solving using lean principles and PDCA methodology.

Plan and execute focused rapid improvement events targeting specific process problems.

Visual signal cards for pull-based material replenishment and production control.

Join manufacturing leaders who are turning operational noise into predictable production rhythm.