Track preventive maintenance, repairs, and equipment history to maximize reliability and uptime.

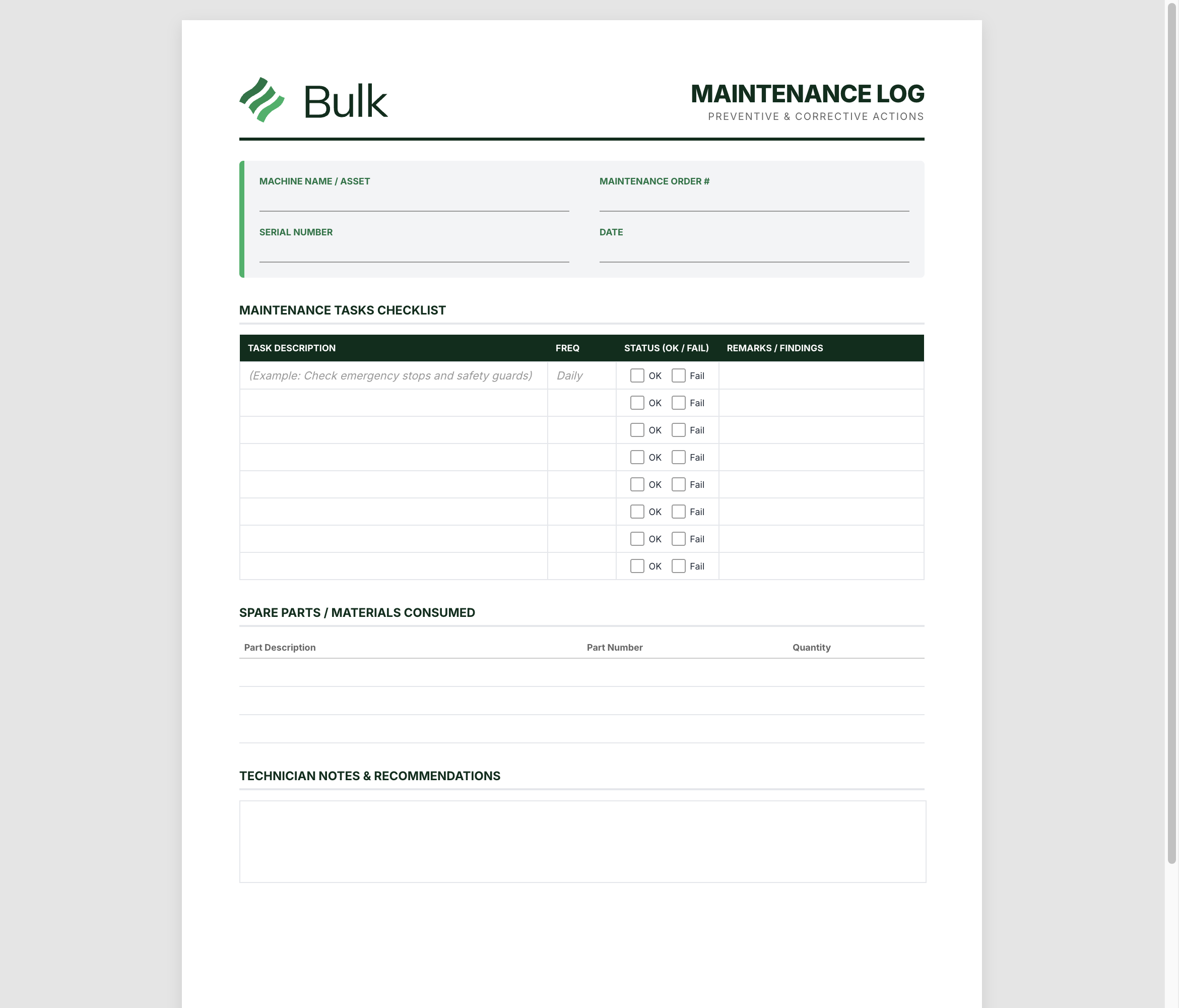

The Equipment Maintenance Log is essential for tracking all maintenance activities on critical production equipment. This template documents preventive maintenance tasks, repairs, parts replacements, and equipment performance over time, creating a comprehensive maintenance history. Regular logging enables predictive maintenance by identifying failure patterns, helps optimize PM schedules, and provides data for equipment reliability improvement. The log format captures work performed, parts used, downtime duration, and costs, supporting both regulatory compliance and continuous improvement of maintenance effectiveness.

Track and optimize equipment setup times for faster changeovers and increased production capacity.

Energy control procedures to protect workers from hazardous energy during equipment maintenance.

Operator-performed equipment maintenance checklist for autonomous maintenance and TPM programs.

Join manufacturing leaders who are turning operational noise into predictable production rhythm.